-

Stainless steel connectorsAs a key link in fluid control systems, our stainless steel fittings are renowned for their exceptional sealing, corrosi...view more

-

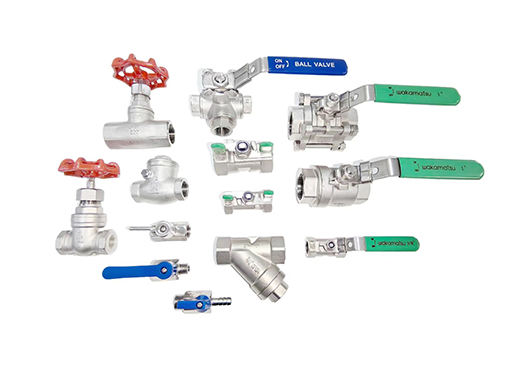

Stainless steel valvesOur stainless steel valve product line offers comprehensive solutions for precise control of fluid on/off and flow. Desi...view more

-

Stainless steel BUTT-WELDING fittingsDesigned to create permanent, high-integrity piping systems, our stainless steel welded fittings achieve seamless connec...view more

-

Stainless steel flangeAs the primary connection and disassembly nodes in piping systems, stainless steel flanges offer unparalleled convenienc...view more

-

Hoses and flexible pipesProviding the ultimate flexible and reliable solution for complex fluid transfer. Designed for demanding applications su...view more

Stainless Steel Tube Fittings In-depth Analysis: Durability, Performance, and Industrial Applications (Complete)

I. Introduction: The Importance of Stainless Steel Tube Fittings

In modern industrial piping systems, connectors are the key components that ensure safe and stable fluid conveyance, and Stainless Steel Tube Fittings (stainless steel tube fittings) are undoubtedly one of the most widely used and reliable types of components. Whether in chemical processing, oil and gas, food processing, marine engineering, or high-pressure hydraulic systems, wherever pipes and fluids exist, high-quality connectors are indispensable.

The reason Stainless Steel Tube Fittings have become the preferred choice in industrial-grade piping systems stems from their unique advantages: corrosion resistance, high structural strength, ability to withstand high temperatures and pressures, and service life that far exceeds that of ordinary materials. Compared with carbon steel or copper connectors, stainless steel fittings are easier to maintain stability in harsh environments and are less prone to leakage or degradation from temperature fluctuations and media corrosion.

With global industrial equipment continually upgrading, enterprises demand higher levels of system safety, maintenance cost control, and fluid control precision. Stainless Steel Tube Fittings can meet these demands effectively. They not only enable reliable connections between different types of metal pipes, hard tubes, or hoses, but also maintain sealing reliability under extreme conditions, preventing leaks that might cause safety incidents and financial losses.

This article will deeply explore the core structures, material properties, industrial application scenarios, and selection and installation techniques of Stainless Steel Tube Fittings. It will also incorporate related concepts such as corrosion resistant tube fittings, industrial stainless steel connectors, high pressure tubing fittings, 316 stainless steel pipe fittings, and compression tube fittings stainless steel, providing a comprehensive and systematic understanding of stainless steel tube connectors.

II. Corrosion Resistant Tube Fittings: The Key to Extending System Life

Corrosion is a challenge every industry with metal piping systems must face. Whether conveying water, oil, steam, gas, or strongly corrosive chemical media, improperly installed or poor-quality connectors will corrode, leading to leaks, blockages, and even system failures. Therefore, corrosion resistant tube fittings are among the most fundamental and crucial needs in industrial environments.

Stainless Steel Tube Fittings possess inherent advantages in corrosion resistance. The chromium content in stainless steel quickly forms a dense oxide film with oxygen in the air. This protective film prevents further oxidation, allowing stainless steel to remain highly stable in humid environments, salt spray, chemical media, and even seawater. This protective action is particularly important for piping systems exposed to corrosive conditions for extended periods.

In the chemical industry, many piping systems contact sulfides, chlorides, or acidic/basic substances. If ordinary materials are used, not only will the connector body corrode, but sealing surfaces may also be damaged, resulting in loosening, seepage, or rupture. Using Stainless Steel Tube Fittings substantially reduces corrosion risk, extends system life, and lowers maintenance workload.

Many hydraulic and instrumentation systems require extremely high cleanliness levels. Corrosion particles entering these systems can cause valve sticking, instrument inaccuracies, or control failures. Stainless Steel Tube Fittings not only resist corrosion themselves but also maintain internal smoothness, preventing particulate contamination of the conveyed medium and better preserving system stability.

From a long-term perspective, corrosion-resistant materials typically cost more initially, yet their lower maintenance costs, longer service life, and reduced failure rates deliver high overall cost-effectiveness. This benefit has driven many industrial enterprises to adopt Stainless Steel Tube Fittings to enhance equipment reliability.

III. Industrial Stainless Steel Connectors: Reliability Advantages in Industrial Environments

In various industrial scenarios, piping systems must meet requirements for high strength, wear resistance, vibration resistance, and adaptability to complex working conditions. The design of industrial stainless steel connectors is centered around meeting these challenges.

Stainless Steel Tube Fittings provide exceptional structural stability. Typical designs use tapered, threaded, or compression structures that achieve high-strength engagement through applied force or torque, allowing them to remain tightly secured under high pressure, frequent vibration, or rapid temperature changes without loosening.

In the oil and gas industry, many devices are installed outdoors or on offshore platforms and endure wind, rain, temperature swings, and continuous pressure fluctuations. Industrial-grade Stainless Steel Tube Fittings deliver sufficient strength and fatigue resistance to maintain sealing integrity. Even with minor pipe displacement or mechanical vibration, stainless steel connectors can maintain a reliable seal through structural self-locking.

Food processing and pharmaceutical industries also heavily rely on stainless steel connectors. Stainless Steel Tube Fittings do not react with conveyed media nor release metal ions, avoiding contamination of fluids. They are well suited for delivering potable water, food-grade liquids, or sensitive chemical solutions. The smooth surface of stainless steel is easy to clean and sterilize, preventing bacterial growth and meeting strict hygiene requirements.

Equipment manufacturing often requires heat resistance. In scenarios involving heating, steam, or hot gas, ordinary connectors can soften or deform, but Stainless Steel Tube Fittings maintain good mechanical properties at elevated temperatures.

Overall, industrial stainless steel connectors are designed to ensure structural strength and sealing reliability, enabling piping systems to operate stably under complex conditions. Stainless Steel Tube Fittings are the most mature and widely used solutions in this domain.

IV. High Pressure Tubing Fittings: Design Considerations for High-Pressure Conditions

Many industrial systems—particularly hydraulic equipment, motion control, and high-pressure gas delivery—operate under high-pressure conditions. Connections in high-pressure systems are frequent sources of safety incidents. High pressure tubing fittings must feature sufficient strength, locking mechanisms, and sealing performance to withstand pressure surges, pulsating pressures, and long-term operational loads.

Stainless Steel Tube Fittings perform exceptionally well in high-pressure scenarios thanks to their robust metallic construction and precisely machined sealing geometries. The most critical issue in high-pressure systems is leakage. Leakage not only results in media loss but can also cause equipment damage, sudden pressure drops, system faulting, and safety hazards. Therefore, selecting appropriate high pressure tubing fittings is crucial to system safety.

In hydraulic systems, pressures can reach tens of MPa or higher, requiring fittings that resist extreme stress without deforming. Stainless Steel Tube Fittings commonly use double ferrule designs, tapered seals, or metal-to-metal compression structures, enabling the fitting to clamp tightly to the pipe wall under torque to form a leak-proof seal. Even under severe vibration, these solid metal structures maintain stability and avoid loosening at sealing surfaces.

High-pressure systems often face pressure pulses—rapid repeated pressure swings that can act thousands of times in a short period—posing high demands on fatigue life. Because Stainless Steel Tube Fittings feature integral structures with fewer stress-concentrating features, they resist fatigue failure better, improving long-term stability.

Additionally, high pressure tubing fittings are particularly vital in gas systems because gas leaks are harder to detect and more dangerous. Stainless Steel Tube Fittings provide reliable gas-tightness to prevent leakage and ensure system pressures remain within safe ranges.

In summary, in all scenarios demanding high pressure, high strength, and high reliability, Stainless Steel Tube Fittings are the most trustworthy choice; their performance advantages are difficult for other materials to match.

V. 316 Stainless Steel Pipe Fittings: The Importance of Material Grades

Within industrial piping systems, different stainless steel grades offer varying corrosion resistance and mechanical properties. Among them, 316 stainless steel stands out for its significantly improved chemical stability and corrosion resistance, leading to wide application in higher-demand environments. Consequently, 316 stainless steel pipe fittings hold a crucial position within the Stainless Steel Tube Fittings category.

The primary difference between 316 and 304 stainless steel is that 316 contains a higher proportion of nickel and the addition of molybdenum. The presence of molybdenum enhances resistance to pitting corrosion in chloride-rich environments, allowing 316 to withstand salt spray, seawater, and chloride-containing solutions. In oil and chemical industries and marine engineering—where fittings are often exposed to high humidity, salinity, and aggressive chemicals—ordinary materials may corrode quickly, weakening structure and causing leakage. 316 stainless steel fittings, however, maintain high stability in such harsh conditions.

Stainless Steel Tube Fittings made from 316 also show advantages when handling acidic or alkaline media. Many chemical media accelerate corrosion at elevated temperatures; molybdenum helps 316 preserve the stability of its passive film at high temperatures, preventing corrosion. This property is crucial for chemical plants, pharmaceutical factories, and systems that handle corrosive waste streams.

Mechanically, 316 stainless steel provides sufficient strength for industrial use. Its higher yield and tensile strengths allow piping systems to withstand high pressures without deformation. Combined with good weldability and machinability, 316 becomes the preferred material for manufacturing high-quality Stainless Steel Tube Fittings.

In sanitary systems like food processing, beverage production, and pure water lines, the surface finish and corrosion resistance of 316 stainless steel reduce bacterial growth and maintain media purity. These characteristics make 316 fittings highly compatible with industries demanding hygiene, non-contamination, and cleanability.

In short, the prominence of 316 stainless steel pipe fittings among Stainless Steel Tube Fittings arises from the combined advantages of corrosion resistance, high-temperature stability, mechanical strength, and sanitary suitability, making them the most reliable connection solution in severe service conditions.

VI. Compression Tube Fittings Stainless Steel: Fast and Stable Installation Methods

Among various types of pipe connectors, compression stainless steel fittings (compression tube fittings stainless steel) are widely used in instrumentation, hydraulics, pneumatics, and chemical systems due to their weld-free installation, convenience, and reliable sealing. Compression fittings are an important category within Stainless Steel Tube Fittings. Their core advantage lies in enabling quick and secure connections without welding.

Compression fittings achieve sealing through the collaboration of a metal ferrule, a nut, and the fitting body. When the nut is tightened, the ferrule deforms uniformly under a tapered surface to bite into the tube wall and form a firm metal-to-metal sealing interface with the fitting. Because this sealing is metal-to-metal, compression fittings have excellent load-bearing capacity and remain reliable even under high pressure.

Compression fittings are particularly valuable in systems requiring frequent disassembly and reassembly, such as instrumentation devices, flow meter installation points, and testing rigs. Welding is impractical for such frequent changes. Compression Stainless Steel Tube Fittings allow maintenance personnel to rapidly perform disassembly and reassembly without heating or welding equipment, saving time and reducing safety risks.

Stainless steel compression fittings also offer strong anti-vibration performance. In many mechanical systems or fluid networks, vibration may cause threaded fittings to loosen, but compression structures rely on a ferrule’s tight bite to resist loosening caused by vibration. This makes them suitable for pumps, engine compartments, heavy machinery, ships, and other vibration-prone scenarios.

Moreover, compression Stainless Steel Tube Fittings maintain sealing stability in extreme high or low temperatures. Welded joints may experience stress from thermal expansion and contraction, whereas the metal sealing mechanism of compression fittings better accommodates temperature variation without compromising sealing surfaces.

From installation flexibility to sealing reliability and adaptability, compression tube fittings stainless steel are indispensable in modern industry. They bring improved efficiency and safety to piping systems.

VII. How to Select the Right Stainless Steel Tube Fittings

For many engineers and equipment manufacturers, selecting the right Stainless Steel Tube Fittings is a critical task. Incorrect selection can lower system efficiency or even cause severe equipment failure and safety incidents. When choosing Stainless Steel Tube Fittings, consider pressure rating, operating environment, medium type, installation method, and compatibility.

First, determine the fitting type and structure according to system pressure. High-pressure systems should prioritize fittings with tapered sealing or metal-to-metal sealing designs, which are more robust under high and pulsating pressures. For lower-pressure systems with limited installation space, compression fittings are compact and convenient, making them suitable for instrumentation and small-diameter piping.

Second, material selection is heavily influenced by the application environment. If the piping is located in humid, outdoor, marine, or chemically aggressive areas, choose corrosion-resistant materials such as 316 stainless steel pipe fittings to ensure long-term durability. In neutral media or ordinary air and water, 304-grade stainless steel fittings may suffice.

Furthermore, the temperature and chemical properties of the conveyed medium determine fitting choice. For high-temperature steam or hot oil, choose structures that withstand elevated temperatures and avoid fatigue damage from thermal cycling. For corrosive liquids, prioritize stainless steel grades containing molybdenum or other high-corrosion-resistance alloys.

Compatibility is another crucial factor. Systems often combine different materials or pipe diameters, so ensure Stainless Steel Tube Fittings match the dimensions, thread specifications, or piping standards to avoid insecure connections, seal failures, or stress concentrations. In systems requiring precise fluid control, internal surface smoothness and flow path design of the fitting should also be considered to prevent flow resistance or vortices.

In summary, selecting the proper Stainless Steel Tube Fittings is a systems engineering task requiring careful judgment based on actual working conditions. Any hasty choice may lead to unexpected harm.

VIII. Installation & Maintenance Recommendations for Stainless Steel Tube Fittings

Even with high-quality Stainless Steel Tube Fittings, improper installation can cause leakage, fatigue failure, or reduced system efficiency. Therefore, correct installation and maintenance are critical to ensuring stable system operation.

During installation, ensure pipe cut ends are square and burr-free; otherwise sealing surfaces cannot fully mate with the pipe wall, potentially leaving tiny gaps that cause long-term leakage. For compression fittings, the ferrule must be fully seated; insufficient seating reduces biting force and compromises sealing. When tightening nuts, follow specified torque ranges to avoid thread damage from over-torquing or incomplete sealing from under-torquing.

In high-pressure systems, use specialized installation tools to achieve optimal sealing with Stainless Steel Tube Fittings. After installation, perform pressure tests to detect any seepage and confirm connections are secure. Avoid applying lateral forces to piping as uneven loading shortens fitting life.

For maintenance, periodically inspect fittings for looseness, corrosion, wear, or deformation due to temperature. Systems subject to heavy vibration should be checked more often to ensure ferrules and threads remain stable. If pipe misalignment occurs, adjust supports or clamps to prevent fittings from bearing excessive mechanical stress.

In extreme environments—chemical solvents, high temperatures, or marine atmospheres—regularly clean and inspect fitting surfaces to avoid long-term buildup of corrosive substances. Proper maintenance not only extends the life of Stainless Steel Tube Fittings but also keeps the entire fluid control system performing optimally.

IX. Conclusion

Stainless Steel Tube Fittings are core connecting components in modern industrial piping systems. With excellent corrosion resistance, high strength, reliable sealing, and broad adaptability across various operating conditions, they have become fundamental elements across many industries. From the corrosion resistance of corrosion resistant tube fittings to the industrial reliability of industrial stainless steel connectors, from the stability of high pressure tubing fittings to the material advantages of 316 stainless steel pipe fittings and the installation convenience of compression tube fittings stainless steel, stainless steel fittings demonstrate their irreplaceable role in complex industrial applications.

Whether in chemical processing, oil and gas, food and medical sectors, or hydraulic control systems, Stainless Steel Tube Fittings play a crucial role in ensuring fluid conveyance safety. Proper selection, standardized installation, and regular maintenance ensure these fittings deliver peak performance and provide solid support for long-term equipment reliability.

As industrial technology continues to advance, demands for piping connection safety and durability will increase. Stainless Steel Tube Fittings will continue to leverage their material and structural advantages to remain indispensable in future industrial development.

English

English 日本語

日本語 中文

中文