The global market for stainless steel threaded fittings, particularly those adhering to NPT (National Pipe Thread) and BSPT (British Standard Pipe Tapered) standards, is experiencing robust growth. Driven by expanding applications in oil and gas, chemical processing, and food-grade industries, manuf...

READ MOREStainless Steel Ferrule Fitting Suppliers

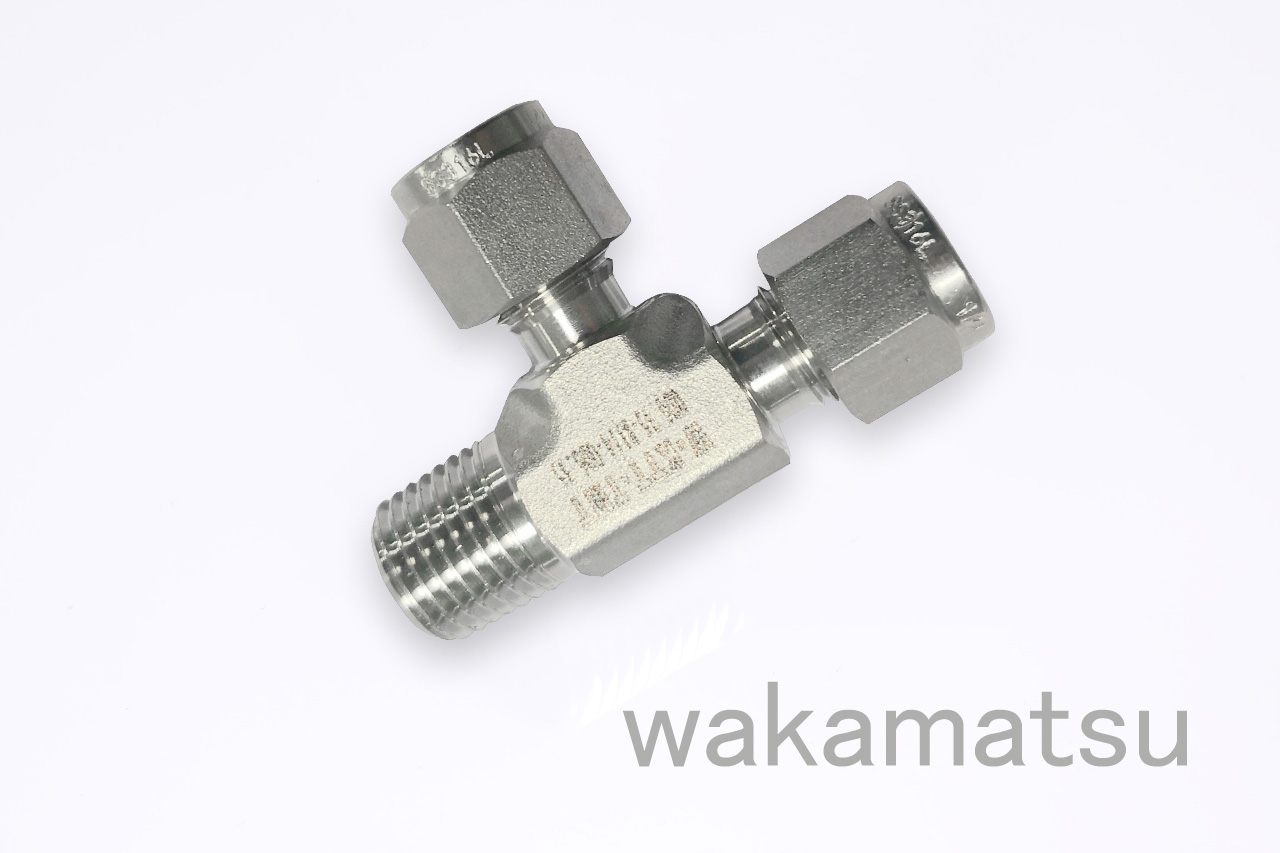

Quickly and securely connect small-diameter pipes for instrumentation, pressure measurement, hydraulic transmission, and other applications without welding or complex tools. Our stainless steel compression fittings utilize a unique ferrule engagement mechanism, offering strong resistance to vibration and pullout. They are easy to install and reusable, significantly improving the efficiency and flexibility of piping for instrumentation panels, analytical equipment, and control systems.

-

Stainless steel connectors

-

Stainless steel threaded connector

- Nipple,VN/VLN stainless steel double-ended male connector

- Nipple,VWN/VWLN stainless steel single-ended male connector

- WMFB/WMFLB stainless steel female connector, extension connector

- Socket,WPTS/WPTSB thin stainless steel double-ended female connector

- Socket,WHPTS/WHPTSB stainless steel single-ended female connector

- Socket,VSO/VHSO stainless steel straight-through female connector

- Socket,WPS stainless steel thick-wall straight-through female connector

- WM6N stainless steel hexagon nipple connector

- WMRN Stainless Steel Hexagon Reducing nippe connector

- WSFG stainless steel hexagonal equal-diameter adapter

- WBU/WMBU stainless steel bushing connectors

- WMF stainless steel male/female adapters

- WMFR stainless steel male/female reducing adapter

- WMS stainless steel flanged female banded socket

- WMRS stainless steel reducing female connectors

- W-KN series stainless steel quick-connect connectors

- VRHN stainless steel round hose connectors

- VRH stainless steel welding hose connectors

- VHS stainless steel hose connectors

- VHJ stainless steel hose connectors

- VHN, WCH, WMCH stainless steel hexagonal male hose fittings

- WCHF stainless steel hexagonal female thread hose fittings

- WCHL stainless steel L-shaped hose fittings

- WMU stainless steel female union fittings

- WMU2 stainless steel external union fittings WMU2 stainless steel male union fittings

- WMU3 stainless steel female and male union fittings

- WMUL stainless steel female union elbow fittings

- WMUL2 stainless steel female and male union elbow fittings

- WML stainless steel 90° elbow fittings

- WMRL stainless steel reducing elbow fittings

- WMSL stainless steel male/female elbow fitting

- WM45L stainless steel 45° elbow fitting

- WMX stainless steel cross fitting

- WMT stainless steel tee fitting

- WMRT stainless steel reducing tee fitting

- WMT-FMF-1/2 stainless steel main/female branch/female tee fitting

- WMT-FFM-1/2 stainless steel main/double female branch/male tee fitting

- WMT-MMF-1/2 stainless steel main/double male branch/female tee fitting

- WMYT-1/2 stainless steel full female tee fitting

- WMP stainless steel square plug fitting

- WMHP stainless steel hexagonal plug connector

- WCP stainless steel inner hexagonal plug connector

- WC stainless steel round pipe cap

- WHC stainless steel hexagonal pipe cap

- Stainless Steel Bulkhead Fittings Tt Series Female Thread/Male Thread

- Stainless Steel Bulkhead Fittings TTM Series Male/Female thread

- WSFG stainless steel hexagonal equal-diameter adapter-副本

-

Stainless steel bite type fittings

- W - Ktz Stainless Steel Straight-Through Bite Type Fitting

- W - KTZR Stainless Steel Reducing Straight-Through Bite Type Fitting

- W - Ktzm Stainless Steel Straight-Through Male Thread Bite Type Fitting

- W - Ktzf Stainless Steel Straight Through Female Thread Bite Type Fitting

- W - Ktl Stainless Steel Elbow Bite Type Fitting

- W - Ktlm Stainless Steel Male Elbow Bite Type Fitting

- W - Ktlf Stainless Steel Female Thread Elbow Bite Type Fitting

- W - Ktt Stainless Steel Tee Bite Type Fitting

- W - Ktt - Tmt Stainless Steel Tee Bite Type Fitting TMT

- W - Ktt - Tft Stainless Steel Tee Bite Type Fitting TFT

- W - Ktt - Ttm Stainless Steel Tee Branch Male Threaded Fitting

- W - Ktt - Ttf Stainless Steel Tee Bite Type Fitting TTF

- W - Ktx Stainless Steel Four-Way Bite Type Fitting

- W - Ktz - Cb Stainless Steel Straight-Through Bite Type Bulkhead Fitting

- W - Ktc Stainless Steel Tube Plug

- W - Ktp Stainless Steel Ferrule End Plug

- W - Ktq Stainless Steel Ferrule Assembly

- W - Ktg Stainless Steel Tube

-

Stainless steel quick connector

- W-Ksa Stainless Steel Quick Connector

- W-Kse Stainless Steel Quick Connector

- W-Ksf Stainless Steel Quick Connector

- W-Ksdp Stainless Steel Quick Connector

- W-Ksc Stainless Steel Handle Quick Connector

- W-Ksd Stainless Steel Handle Quick Connector

- W-Ksb Stainless Steel Lever Type Quick Connector

- W-Ksdc Stainless Steel Handle Quick Connector

- Stainless steel VCR connector

-

Stainless steel threaded connector

-

Stainless steel valves

-

Stainless steel ball valve

- Wv101/Wv101b Stainless Steel One-Piece Ball Valve

- Wv102/Wv102b Stainless Steel Two-Piece Ball Valve

- Wv102fm Stainless Steel Two-Piece Female And Male Thread Ball Valve

- Wv103 Stainless Steel Three-Piece Ball Valve

- Wv104 Stainless Steel Three-Way Ball Valve

- Wv301 Stainless Steel One-Piece Flange Ball Valve

- Wv302 Stainless Steel Two-Piece Flange Ball Valve

- Wv201ff Mini Stainless Steel Female Thread Ball Valve

- Wv202mm Mini Stainless Steel Male Ball Valve

- Wv203fm Mini Stainless Steel Female And Male Thread Ball Valve

- Wv204hm Pagoda-Shaped Stainless Steel Mini Male Ball Valve

- Wv205hf Pagoda-Shaped Stainless Steel Mini Female Ball Valve

- Stainless steel Y-type strainer

- Stainless steel gate valve/globe valve/check valve

- Stainless steel needle valve

-

Stainless steel ball valve

-

Stainless steel BUTT-WELDING fittings

-

Stainless steel flange

- Hoses and flexible pipes

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

Features: Live-load and dual-ferrule design; The nut is coated to prevent seizing during installation and allows for repeated disassembly and reuse.VIEW MORE

-

-

Introduction Stainless steel butt weld fittings are crucial components in industrial piping systems, used for connecting pipes, valves, and other equipment. These fittings are welded to the pipes using a butt weld technique, ensuring a strong, leak-proof, and durable connection. Butt weld fittings a...

READ MORE -

What Is a Stainless Steel Camlock Coupling? A Stainless Steel Camlock (technically known as a Cam and Groove Coupling) is a quick-disconnect fluid transfer fitting that allows operators to connect or disconnect hoses without tools in seconds. Unlike threaded fittings or flanges that require wrenches...

READ MORE

Stainless Steel Bite-Type Fittings vs. Double Ferrule Fittings: A Technical Guide for Secure Connections

In the world of industrial and building services piping, selecting the right connection method is critical for system integrity, safety, and longevity. Two prominent solutions for stainless steel tubing are Stainless Steel Bite-Type Fittings and Double Ferrule Compression Fittings. While both create reliable, leak-free joints, their principles, applications, and installation requirements differ significantly. This guide, informed by the precision manufacturing expertise of Shanghai Wakamatsu Metal Products Co., Ltd., will explore these differences to aid in proper selection. Strategically located in the Yangtze River Delta ecological development zone, Shanghai Wakamatsu leverages advanced CNC machining and a commitment to quality to supply these critical components to global markets in building, medical, fire safety, and industrial sectors.

Comparative Analysis: Bite-Type vs. Double Ferrule Fittings

| Aspect | Stainless Steel Bite-Type Fittings | Double Ferrule Compression Fittings |

| Connection Principle | Radial compression of a sleeve onto the tube using a special tool, creating a permanent "bite" and mechanical seal. | Axial compression via a nut drives a front ferrule to bite the tube and a back ferrule to provide grip, creating a seal and hold. |

| Key Characteristics | Permanent, high strength at joint, vibration-resistant, fast installation, requires dedicated tooling. | Demountable/re-makeable, excellent vibration resistance, more tolerant to tube variations, requires installer skill. |

| Typical Tube Used | Thin-walled stainless steel tube (e.g., metric sizes DN15-DN100). | Thin or thick-walled stainless steel, copper, nylon (e.g., imperial sizes 1/8" - 2"). |

| Primary Applications | Potable water systems, medical gas lines, food & beverage, fixed plumbing where no future disassembly is planned. | Instrumentation lines, hydraulic/pneumatic systems, process control, analytical equipment, fire suppression detection lines. |

| Installation Focus | Tool calibration, square tube cut, deburring. Process is fast and irreversible. | Precise torque or turn-count procedure (e.g., 1.25-1.5 turns past hand-tight). Skill-dependent but allows for maintenance. |

Stainless Steel Bite-Type Fittings: The Permanent System Solution

Bite-type fittings represent a breakthrough for clean, permanent piping systems. The process creates a joint whose strength rivals the tube itself, eliminating common failure points of threaded connections.

Advantages and Selection Criteria

- Hygienic & Safe: The smooth bore and all-metal, crevice-free seal prevent bacterial growth and contamination, making it ideal for medical gas and drinking water.

- Speed and Reliability: Once the tool is calibrated, installation is consistent and rapid, reducing labor costs and human error on large projects like architectural water supply.

- Critical Parameters for Success:

- Tube Compatibility: Must match the fitting's metric size system and material grade (e.g., SUS304).

- Tooling: Manufacturer-specific press tools are required to achieve the correct compression force and profile.

- Sealing Element: The integrated EPDM or silicone O-ring must be compatible with the fluid service temperature and media.

Double Ferrule Compression Fittings: The Precision Serviceable Connection

Double ferrule fittings are the cornerstone of precision fluid and gas control systems where maintenance and configurability are essential.

Advantages and Installation Mastery

- Serviceability: The ability to disconnect and remake the connection at the same fitting body is invaluable for industrial facility maintenance and instrumentation calibration.

- High-Pressure Performance: The dual ferrule design provides exceptional resistance to vibration and pressure cycling, crucial for hydraulic and fire-fighting equipment sensing lines.

- The Art of Installation:

- Precision Cutting: A square cut and proper deburring are non-negotiable.

- The "Feel": Following the manufacturer's specified turn-count (e.g., 1-1/4 turns) is more reliable than torque for ensuring the front ferrule bites and the back ferrule grips correctly.

- Ferrule Reuse: While possible, replacing ferrules during major disassembly is recommended for guaranteed seal integrity.

FAQ

Can you mix and match bite-type fittings and tools from different manufacturers?

It is strongly discouraged and often leads to system failure. Bite-type fittings are part of a proprietary system. The sleeve geometry, O-ring size, and the pressing profile of the tool are precisely engineered to work together. Using a tool from Brand A on a fitting from Brand B will likely result in under or over-compression, compromising the seal and the mechanical grip. Always use the complete system—tube, fittings, and tooling—from a single reputable manufacturer or a verified compatible set.

Why does my double ferrule fitting still leak after I've tightened it beyond the recommended torque?

Overtightening is a common mistake that can cause leaks rather than prevent them. Excessive torque can:

- Over-compress the front ferrule, distorting its biting edges and destroying its sealing capability.

- Gall or damage the threads on the fitting body or nut.

- Severely work-harden and potentially crack the tube beneath the ferrule.

The correct procedure is finger-tight plus the specified fractional turn (e.g., 1.25). If it leaks after proper installation, disassemble and inspect: the tube cut may not be square, burrs may be present, or the ferrules/tube may have been damaged during a previous over-tightening attempt.

Are stainless steel bite-type fittings suitable for outdoor or underground installations?

Yes, but with critical considerations. While the stainless steel itself offers excellent corrosion resistance, the integrated elastomeric seal is the limiting factor.

- Material: Ensure the O-ring is made from EPDM for weather/ozone resistance or FKM for broader chemical resistance, not standard NBR.

- Protection: For direct burial, the fitting should be wrapped or sleeved to protect the seal from direct soil contact and abrasion. In exposed outdoor applications, ensure the seal material is rated for the full temperature range and UV exposure.

- Inspection: As a permanent joint, its integrity depends on the initial installation. It is not serviceable like a threaded joint, so proper selection and installation are paramount for inaccessible applications.

What is the main advantage of a double ferrule design over a single ferrule design?

The primary advantage is independent, dual functionality, leading to superior performance in dynamic systems.

- Front Ferrule: Its primary job is to create a leak-tight seal by precisely biting into the tube.

- Back Ferrule: Its primary job is to provide a strong mechanical grip on the tube to prevent pull-out, especially under vibration and pressure cycles. It also helps to isolate the sealing action of the front ferrule from piping stresses.

In a single ferrule design, one component must attempt both sealing and gripping, which can be less effective, especially with harder tubing or in high-vibration environments. The double ferrule design is the industry standard for critical instrumentation and process applications.

How do I choose between a bite-type system and a double ferrule system for a new project?

Follow this decision matrix based on core project requirements:

- Choose Bite-Type Fittings if: Your system is permanent (e.g., building water supply, medical gas), prioritizes hygiene and speed of installation, uses metric thin-walled stainless tube, and has a sufficient budget for the dedicated press tooling.

- Choose Double Ferrule Fittings if: Your system requires future maintenance or reconfiguration (e.g., industrial machinery, lab equipment), uses imperial-sized tubing (or a mix of materials), operates under high vibration/pressure, and where installer skill is available to ensure proper assembly.

For complex projects, consulting with a technical specialist from a manufacturer like Shanghai Wakamatsu, which produces both types, can provide unbiased guidance tailored to your specific technical and commercial needs.

English

English 日本語

日本語 中文

中文