The global market for stainless steel threaded fittings, particularly those adhering to NPT (National Pipe Thread) and BSPT (British Standard Pipe Tapered) standards, is experiencing robust growth. Driven by expanding applications in oil and gas, chemical processing, and food-grade industries, manuf...

READ MOREStainless Steel Butt Weld VCR Fitting Suppliers

VCR (Vacuum Coupling Radius) fittings are renowned for their zero-leakage and repeatable disassembly and installation. Each fitting is manufactured using fully automated orbital welding or precision machining to ensure dimensional accuracy and consistent performance. While the disposable nature of the metal gasket increases the cost per use, it provides the highest level of system safety and reliability, complying with industry standards such as SEMI and ASME BPE. They are the ideal choice for fluid systems operating in cleanrooms and harsh environments.

-

Stainless steel connectors

-

Stainless steel threaded connector

- Nipple,VN/VLN stainless steel double-ended male connector

- Nipple,VWN/VWLN stainless steel single-ended male connector

- WMFB/WMFLB stainless steel female connector, extension connector

- Socket,WPTS/WPTSB thin stainless steel double-ended female connector

- Socket,WHPTS/WHPTSB stainless steel single-ended female connector

- Socket,VSO/VHSO stainless steel straight-through female connector

- Socket,WPS stainless steel thick-wall straight-through female connector

- WM6N stainless steel hexagon nipple connector

- WMRN Stainless Steel Hexagon Reducing nippe connector

- WSFG stainless steel hexagonal equal-diameter adapter

- WBU/WMBU stainless steel bushing connectors

- WMF stainless steel male/female adapters

- WMFR stainless steel male/female reducing adapter

- WMS stainless steel flanged female banded socket

- WMRS stainless steel reducing female connectors

- W-KN series stainless steel quick-connect connectors

- VRHN stainless steel round hose connectors

- VRH stainless steel welding hose connectors

- VHS stainless steel hose connectors

- VHJ stainless steel hose connectors

- VHN, WCH, WMCH stainless steel hexagonal male hose fittings

- WCHF stainless steel hexagonal female thread hose fittings

- WCHL stainless steel L-shaped hose fittings

- WMU stainless steel female union fittings

- WMU2 stainless steel external union fittings WMU2 stainless steel male union fittings

- WMU3 stainless steel female and male union fittings

- WMUL stainless steel female union elbow fittings

- WMUL2 stainless steel female and male union elbow fittings

- WML stainless steel 90° elbow fittings

- WMRL stainless steel reducing elbow fittings

- WMSL stainless steel male/female elbow fitting

- WM45L stainless steel 45° elbow fitting

- WMX stainless steel cross fitting

- WMT stainless steel tee fitting

- WMRT stainless steel reducing tee fitting

- WMT-FMF-1/2 stainless steel main/female branch/female tee fitting

- WMT-FFM-1/2 stainless steel main/double female branch/male tee fitting

- WMT-MMF-1/2 stainless steel main/double male branch/female tee fitting

- WMYT-1/2 stainless steel full female tee fitting

- WMP stainless steel square plug fitting

- WMHP stainless steel hexagonal plug connector

- WCP stainless steel inner hexagonal plug connector

- WC stainless steel round pipe cap

- WHC stainless steel hexagonal pipe cap

- Stainless Steel Bulkhead Fittings Tt Series Female Thread/Male Thread

- Stainless Steel Bulkhead Fittings TTM Series Male/Female thread

- WSFG stainless steel hexagonal equal-diameter adapter-副本

-

Stainless steel bite type fittings

- W - Ktz Stainless Steel Straight-Through Bite Type Fitting

- W - KTZR Stainless Steel Reducing Straight-Through Bite Type Fitting

- W - Ktzm Stainless Steel Straight-Through Male Thread Bite Type Fitting

- W - Ktzf Stainless Steel Straight Through Female Thread Bite Type Fitting

- W - Ktl Stainless Steel Elbow Bite Type Fitting

- W - Ktlm Stainless Steel Male Elbow Bite Type Fitting

- W - Ktlf Stainless Steel Female Thread Elbow Bite Type Fitting

- W - Ktt Stainless Steel Tee Bite Type Fitting

- W - Ktt - Tmt Stainless Steel Tee Bite Type Fitting TMT

- W - Ktt - Tft Stainless Steel Tee Bite Type Fitting TFT

- W - Ktt - Ttm Stainless Steel Tee Branch Male Threaded Fitting

- W - Ktt - Ttf Stainless Steel Tee Bite Type Fitting TTF

- W - Ktx Stainless Steel Four-Way Bite Type Fitting

- W - Ktz - Cb Stainless Steel Straight-Through Bite Type Bulkhead Fitting

- W - Ktc Stainless Steel Tube Plug

- W - Ktp Stainless Steel Ferrule End Plug

- W - Ktq Stainless Steel Ferrule Assembly

- W - Ktg Stainless Steel Tube

-

Stainless steel quick connector

- W-Ksa Stainless Steel Quick Connector

- W-Kse Stainless Steel Quick Connector

- W-Ksf Stainless Steel Quick Connector

- W-Ksdp Stainless Steel Quick Connector

- W-Ksc Stainless Steel Handle Quick Connector

- W-Ksd Stainless Steel Handle Quick Connector

- W-Ksb Stainless Steel Lever Type Quick Connector

- W-Ksdc Stainless Steel Handle Quick Connector

- Stainless steel VCR connector

-

Stainless steel threaded connector

-

Stainless steel valves

-

Stainless steel ball valve

- Wv101/Wv101b Stainless Steel One-Piece Ball Valve

- Wv102/Wv102b Stainless Steel Two-Piece Ball Valve

- Wv102fm Stainless Steel Two-Piece Female And Male Thread Ball Valve

- Wv103 Stainless Steel Three-Piece Ball Valve

- Wv104 Stainless Steel Three-Way Ball Valve

- Wv301 Stainless Steel One-Piece Flange Ball Valve

- Wv302 Stainless Steel Two-Piece Flange Ball Valve

- Wv201ff Mini Stainless Steel Female Thread Ball Valve

- Wv202mm Mini Stainless Steel Male Ball Valve

- Wv203fm Mini Stainless Steel Female And Male Thread Ball Valve

- Wv204hm Pagoda-Shaped Stainless Steel Mini Male Ball Valve

- Wv205hf Pagoda-Shaped Stainless Steel Mini Female Ball Valve

- Stainless steel Y-type strainer

- Stainless steel gate valve/globe valve/check valve

- Stainless steel needle valve

-

Stainless steel ball valve

-

Stainless steel BUTT-WELDING fittings

-

Stainless steel flange

- Hoses and flexible pipes

-

-

Introduction Stainless steel butt weld fittings are crucial components in industrial piping systems, used for connecting pipes, valves, and other equipment. These fittings are welded to the pipes using a butt weld technique, ensuring a strong, leak-proof, and durable connection. Butt weld fittings a...

READ MORE -

What Is a Stainless Steel Camlock Coupling? A Stainless Steel Camlock (technically known as a Cam and Groove Coupling) is a quick-disconnect fluid transfer fitting that allows operators to connect or disconnect hoses without tools in seconds. Unlike threaded fittings or flanges that require wrenches...

READ MORE

How Stainless Steel Butt Weld VCR Fittings Enhance Leak-Free Performance in Semiconductor and Pharmaceutical Applications

Stainless steel butt weld VCR fittings are widely recognized for their exceptional sealing capability and structural integrity, making them a preferred choice in industries where cleanliness and precision are critical. In semiconductor manufacturing and pharmaceutical processing, even tiny leaks can compromise product quality, introduce contaminants, or disrupt controlled environments. For this reason, choosing the right connection technology is essential.

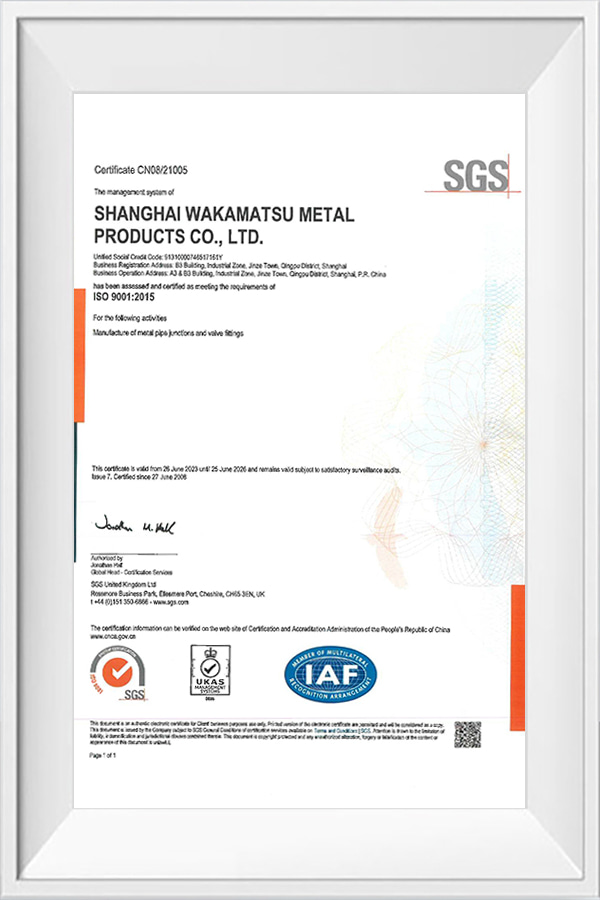

Company Background

Founded in 2003, Shanghai Wakamatsu is a Japan-funded manufacturer specializing in stainless steel screwed fittings, valves, and bite type tube fittings. With over two decades of industry expertise, the company combines Japanese precision manufacturing with advanced production facilities to deliver high-quality solutions for global clients. Its products are trusted across Japan, Europe, and Southeast Asia.

Superior Weld Integrity for Leak-Free Performance

Butt weld VCR fittings eliminate threaded connections and mechanical joints, reducing potential leak paths. The weld-to-tube connection creates a continuous, robust bond that withstands high pressure, frequent thermal cycling, and vibration. This feature is especially important in semiconductor fabs, where ultra-high purity gases must remain contaminant-free throughout the distribution system.

High-Purity Stainless Steel for Cleanroom Requirements

These fittings are typically made from high-grade stainless steel, ensuring resistance to corrosion, particle shedding, and chemical interaction. Their smooth internal surface reduces dead space where contaminants could accumulate, supporting the stringent cleanliness standards required in pharmaceutical formulation and sterile production lines.

Consistent Sealing Using VCR Metal Gasket Technology

The VCR design uses a metal gasket that deforms precisely during assembly to create a clean, repeatable metal-to-metal seal. Unlike elastomer seals, metal gaskets do not degrade under heat, steam sterilization, or aggressive cleaning chemicals. This ensures long-term leak-free operation, even under extreme processing conditions such as ultra-high-purity gas delivery or aseptic pharmaceutical production.

Enhanced Durability for Harsh Operating Conditions

In high-temperature or chemically reactive environments, stainless steel butt weld VCR fittings maintain structural stability better than plastic or compression-style connectors. Their ability to tolerate repeated sterilization, high-pressure flushing, and corrosive process media makes them ideal for continuous use in demanding facilities.

Reduced Maintenance and Improved System Reliability

By minimizing potential leak points and providing stable long-term sealing, these fittings help reduce maintenance frequency and improve overall system uptime. Semiconductor and pharmaceutical operations rely heavily on stable, interruption-free performance, making the reliability of the piping system a critical success factor.

Conclusion

Stainless steel butt weld VCR fittings offer unmatched sealing performance, durability, and purity, making them indispensable in semiconductor and pharmaceutical applications. Their robust weld joints, metal gasket technology, and high-grade stainless steel construction ensure clean, stable, and leak-free system performance across highly sensitive production environments. These advantages allow manufacturers to maintain strict quality control, extend equipment lifespan, and support the demanding requirements of modern high-purity industries.

Comparing Butt Weld VCR Fittings with Traditional Compression Fittings in Ultra High Purity Environments

In ultra high purity environments such as semiconductor fabrication, pharmaceutical processing, and precision laboratory systems, the choice of fitting technology directly affects system cleanliness, leak integrity, and overall operational stability. A modern solution such as the Stainless Steel Butt Weld VCR Fitting provides performance advantages that traditional compression fittings cannot fully match.

Sealing Integrity

Butt weld VCR fittings use a continuous welded connection combined with a metal gasket VCR seal, which minimizes potential leak points. This makes them highly reliable for applications requiring near zero leakage. Traditional compression fittings rely on ferrules to create a seal, and these ferrules can degrade over time due to vibration, thermal cycling, or variations in installation technique.

Cleanliness and Contamination Control

Ultra high purity systems require smooth internal surfaces and minimal dead volume. Butt weld VCR fittings create a seamless internal flow path with no gaps that can trap contaminants. Compression fittings have more internal crevices due to their mechanical components, increasing the risk of particle generation or contamination buildup.

Durability Under Harsh Conditions

Metal to metal VCR sealing technology offers excellent stability under high temperatures, aggressive chemicals, and frequent cleaning cycles. Compression fittings, especially those that include elastomeric elements, may be more vulnerable to chemical attack or heat related fatigue, reducing long term reliability.

Installation Precision and Repeatability

Butt weld VCR fittings require precise welding during installation, but once installed, they offer consistent sealing performance over long service periods. Compression fittings are easier to install but rely heavily on proper torque and assembly technique. Small installation errors can affect sealing quality and system repeatability.

Overall System Reliability

For applications where long term stability, purity, and leak free operation are critical, butt weld VCR fittings provide a superior solution. Traditional compression fittings remain suitable for general industrial applications but may not fully meet the demanding requirements of ultra high purity gas or fluid distribution systems.

While compression fittings are practical and widely used, butt weld VCR fittings offer higher sealing integrity, improved cleanliness, and better durability in challenging ultra high purity environments. Their robust design and consistent sealing performance make them the preferred choice for semiconductor, pharmaceutical, and advanced laboratory applications.

English

English 日本語

日本語 中文

中文