The global market for stainless steel threaded fittings, particularly those adhering to NPT (National Pipe Thread) and BSPT (British Standard Pipe Tapered) standards, is experiencing robust growth. Driven by expanding applications in oil and gas, chemical processing, and food-grade industries, manuf...

READ MOREStainless Steel Control Valve Manufacturers

Our stainless steel valve product line offers comprehensive solutions for precise control of fluid on/off and flow. Designed for corrosive media and environments requiring stringent hygienic standards, all valves are precision-cast and machined for superior sealing and long life. Whether for on/off control or flow regulation, these valves meet your demanding application needs in the chemical, water treatment, energy, and high-end manufacturing industries.

-

Stainless steel connectors

-

Stainless steel threaded connector

- Nipple,VN/VLN stainless steel double-ended male connector

- Nipple,VWN/VWLN stainless steel single-ended male connector

- WMFB/WMFLB stainless steel female connector, extension connector

- Socket,WPTS/WPTSB thin stainless steel double-ended female connector

- Socket,WHPTS/WHPTSB stainless steel single-ended female connector

- Socket,VSO/VHSO stainless steel straight-through female connector

- Socket,WPS stainless steel thick-wall straight-through female connector

- WM6N stainless steel hexagon nipple connector

- WMRN Stainless Steel Hexagon Reducing nippe connector

- WSFG stainless steel hexagonal equal-diameter adapter

- WBU/WMBU stainless steel bushing connectors

- WMF stainless steel male/female adapters

- WMFR stainless steel male/female reducing adapter

- WMS stainless steel flanged female banded socket

- WMRS stainless steel reducing female connectors

- W-KN series stainless steel quick-connect connectors

- VRHN stainless steel round hose connectors

- VRH stainless steel welding hose connectors

- VHS stainless steel hose connectors

- VHJ stainless steel hose connectors

- VHN, WCH, WMCH stainless steel hexagonal male hose fittings

- WCHF stainless steel hexagonal female thread hose fittings

- WCHL stainless steel L-shaped hose fittings

- WMU stainless steel female union fittings

- WMU2 stainless steel external union fittings WMU2 stainless steel male union fittings

- WMU3 stainless steel female and male union fittings

- WMUL stainless steel female union elbow fittings

- WMUL2 stainless steel female and male union elbow fittings

- WML stainless steel 90° elbow fittings

- WMRL stainless steel reducing elbow fittings

- WMSL stainless steel male/female elbow fitting

- WM45L stainless steel 45° elbow fitting

- WMX stainless steel cross fitting

- WMT stainless steel tee fitting

- WMRT stainless steel reducing tee fitting

- WMT-FMF-1/2 stainless steel main/female branch/female tee fitting

- WMT-FFM-1/2 stainless steel main/double female branch/male tee fitting

- WMT-MMF-1/2 stainless steel main/double male branch/female tee fitting

- WMYT-1/2 stainless steel full female tee fitting

- WMP stainless steel square plug fitting

- WMHP stainless steel hexagonal plug connector

- WCP stainless steel inner hexagonal plug connector

- WC stainless steel round pipe cap

- WHC stainless steel hexagonal pipe cap

- Stainless Steel Bulkhead Fittings Tt Series Female Thread/Male Thread

- Stainless Steel Bulkhead Fittings TTM Series Male/Female thread

- WSFG stainless steel hexagonal equal-diameter adapter-副本

-

Stainless steel bite type fittings

- W - Ktz Stainless Steel Straight-Through Bite Type Fitting

- W - KTZR Stainless Steel Reducing Straight-Through Bite Type Fitting

- W - Ktzm Stainless Steel Straight-Through Male Thread Bite Type Fitting

- W - Ktzf Stainless Steel Straight Through Female Thread Bite Type Fitting

- W - Ktl Stainless Steel Elbow Bite Type Fitting

- W - Ktlm Stainless Steel Male Elbow Bite Type Fitting

- W - Ktlf Stainless Steel Female Thread Elbow Bite Type Fitting

- W - Ktt Stainless Steel Tee Bite Type Fitting

- W - Ktt - Tmt Stainless Steel Tee Bite Type Fitting TMT

- W - Ktt - Tft Stainless Steel Tee Bite Type Fitting TFT

- W - Ktt - Ttm Stainless Steel Tee Branch Male Threaded Fitting

- W - Ktt - Ttf Stainless Steel Tee Bite Type Fitting TTF

- W - Ktx Stainless Steel Four-Way Bite Type Fitting

- W - Ktz - Cb Stainless Steel Straight-Through Bite Type Bulkhead Fitting

- W - Ktc Stainless Steel Tube Plug

- W - Ktp Stainless Steel Ferrule End Plug

- W - Ktq Stainless Steel Ferrule Assembly

- W - Ktg Stainless Steel Tube

-

Stainless steel quick connector

- W-Ksa Stainless Steel Quick Connector

- W-Kse Stainless Steel Quick Connector

- W-Ksf Stainless Steel Quick Connector

- W-Ksdp Stainless Steel Quick Connector

- W-Ksc Stainless Steel Handle Quick Connector

- W-Ksd Stainless Steel Handle Quick Connector

- W-Ksb Stainless Steel Lever Type Quick Connector

- W-Ksdc Stainless Steel Handle Quick Connector

- Stainless steel VCR connector

-

Stainless steel threaded connector

-

Stainless steel valves

-

Stainless steel ball valve

- Wv101/Wv101b Stainless Steel One-Piece Ball Valve

- Wv102/Wv102b Stainless Steel Two-Piece Ball Valve

- Wv102fm Stainless Steel Two-Piece Female And Male Thread Ball Valve

- Wv103 Stainless Steel Three-Piece Ball Valve

- Wv104 Stainless Steel Three-Way Ball Valve

- Wv301 Stainless Steel One-Piece Flange Ball Valve

- Wv302 Stainless Steel Two-Piece Flange Ball Valve

- Wv201ff Mini Stainless Steel Female Thread Ball Valve

- Wv202mm Mini Stainless Steel Male Ball Valve

- Wv203fm Mini Stainless Steel Female And Male Thread Ball Valve

- Wv204hm Pagoda-Shaped Stainless Steel Mini Male Ball Valve

- Wv205hf Pagoda-Shaped Stainless Steel Mini Female Ball Valve

- Stainless steel Y-type strainer

- Stainless steel gate valve/globe valve/check valve

- Stainless steel needle valve

-

Stainless steel ball valve

-

Stainless steel BUTT-WELDING fittings

-

Stainless steel flange

- Hoses and flexible pipes

-

Specifications Maximum allowable pressure: 4.12 MPa for water, oil, and gas at room temperature; 0.5 MPa for saturated steam. Seal check pressure: 0.59 MPa. Operating temperature range: -20°C to 180°C...VIEW MORE

-

Specifications Maximum allowable pressure: 5.49 MPa for water, oil, and gas at room temperature; 0.5 MPa for saturated steam. Seal check pressure: 0.59 MPa. Operating temperature range: -20°C to 180°C...VIEW MORE

-

Specifications Maximum allowable pressure: 5.49 MPa for water, oil, and gas at room temperature; 0.5 MPa for saturated steam. Seal check pressure: 0.59 MPa. Operating temperature range: -20°C to 180°C...VIEW MORE

-

Specifications Maximum allowable pressure: 6.86 MPa for water, oil, and gas at room temperature; 0.5 MPa for saturated steam. Seal check pressure: 0.59 MPa. Operating temperature range: -20°C to 180°C...VIEW MORE

-

Specifications Maximum allowable pressure: 6.3 MPa for water, oil, and gas at room temperature; 0.5 MPa for saturated steam. Seal check pressure: 0.59 MPa. Operating temperature range: -20°C to 180°C....VIEW MORE

-

Specifications Applicable media: Water, oil, and gas. Applicable temperature: −20°C to +180°C. Maximum allowable pressure: 2 MPa (room temperature). Flange specifications: DIN 2501.VIEW MORE

-

Specifications Applicable media: Water, oil, and gas. Applicable temperature: −20°C to +180°C. Maximum allowable pressure: 2 MPa (normal temperature). Flange specifications: JIS B2220 10K.VIEW MORE

-

Specifications Maximum allowable pressure: 4.0 MPa for water, oil, and gas at room temperature. Seal check pressure: 0.59 MPa. Operating temperature range: -20°C to 150°C.VIEW MORE

-

Specifications Maximum allowable pressure: 4.0 MPa for water, oil, and gas at room temperature. Seal check pressure: 0.59 MPa. Operating temperature range: -20°C to 150°C.VIEW MORE

-

Specifications Maximum allowable pressure: 4.0 MPa for water, oil, and gas at room temperature. Seal check pressure: 0.59 MPa. Operating temperature range: -20°C to 150°C.VIEW MORE

-

Specifications Maximum allowable pressure: 4.0 MPa for water, oil, and gas at room temperature. Seal check pressure: 0.59 MPa. Operating temperature range: -20°C to 150°C.VIEW MORE

-

Specifications Maximum allowable pressure: 4.0 MPa for water, oil, and gas at room temperature. Seal check pressure: 0.59 MPa. Operating temperature range: -20°C to 150°C.VIEW MORE

-

-

Introduction Stainless steel butt weld fittings are crucial components in industrial piping systems, used for connecting pipes, valves, and other equipment. These fittings are welded to the pipes using a butt weld technique, ensuring a strong, leak-proof, and durable connection. Butt weld fittings a...

READ MORE -

What Is a Stainless Steel Camlock Coupling? A Stainless Steel Camlock (technically known as a Cam and Groove Coupling) is a quick-disconnect fluid transfer fitting that allows operators to connect or disconnect hoses without tools in seconds. Unlike threaded fittings or flanges that require wrenches...

READ MORE

How is a stainless steel control valve different from other types of control valves?

A stainless steel control valve is an essential component in fluid control systems, designed to regulate flow, pressure, and temperature within pipelines. Unlike conventional control valves, stainless steel variants provide superior corrosion resistance, durability, and precision, making them suitable for a wide range of demanding industries, including chemical processing, water treatment, energy, and high-end manufacturing.

Material Advantages of Stainless Steel Control Valve

Corrosion and Chemical Resistance

One of the primary distinctions of a stainless steel control valve is its resistance to corrosion. While traditional valves may be constructed from carbon steel, brass, or plastic, stainless steel provides a robust barrier against corrosive media, including acids, alkaline solutions, and saline environments. This property makes stainless steel valves ideal for chemical plants, wastewater treatment facilities, and applications involving aggressive fluids.

Durability and Longevity

Stainless steel control valves exhibit superior mechanical strength, reducing wear and tear under high-pressure and high-temperature conditions. Their longevity is often greater than valves made from other metals, minimizing replacement frequency and operational interruptions. This durability is critical for industries where system downtime can result in significant financial loss.

Hygiene and Purity Compliance

Unlike traditional valves, stainless steel variants are often required in food, beverage, and pharmaceutical applications due to their hygienic properties. Stainless steel surfaces resist microbial growth and are easy to clean, ensuring that fluid systems meet stringent health and safety standards.

Design and Manufacturing Considerations

Precision Engineering

The manufacturing of stainless steel control valves relies on precision machining, which is critical for achieving tight sealing and smooth flow regulation. Advanced production techniques, including CNC processing, turning, milling, and polishing, allow manufacturers to produce valves with highly consistent performance.

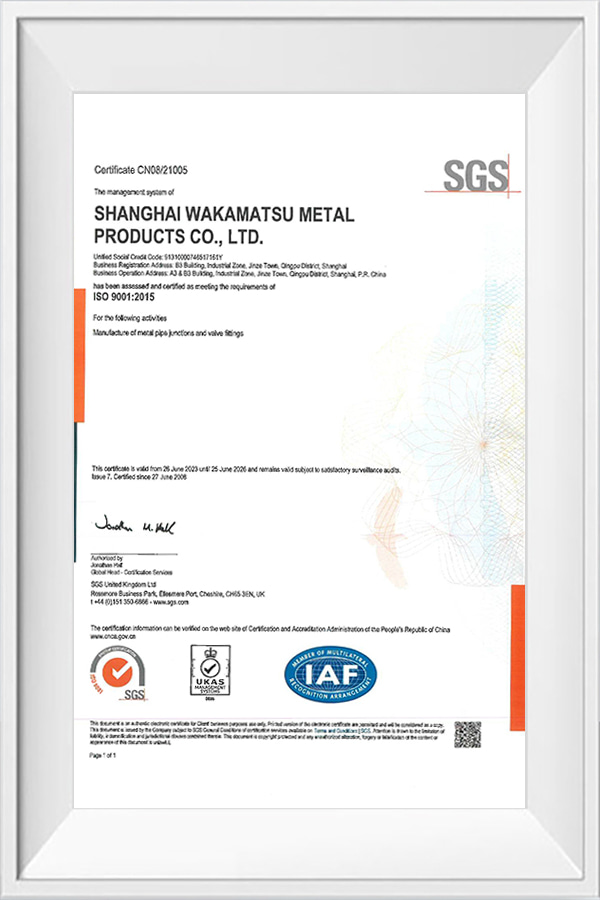

At Shanghai Wakamatsu Metal Products Co., Ltd., full-process manufacturing ensures that each stainless steel component—from threaded fittings to valves—is produced according to exacting specifications. This level of control ensures that valves perform reliably in both on/off and modulating applications.

Versatility in Valve Types

Stainless steel control valves are available in multiple configurations, including globe, ball, butterfly, and diaphragm types. Each design has its advantages:

| Valve Type | Primary Use | Key Advantage |

|---|---|---|

| Globe | Flow regulation | Precise throttling control |

| Ball | On/off control | Minimal leakage, quick operation |

| Butterfly | Large-diameter pipelines | Compact and lightweight |

| Diaphragm | Corrosive or sanitary fluids | Leak-proof and easy to maintain |

The selection of a particular type depends on the fluid characteristics, pressure requirements, and the operational environment. This flexibility is not always available with conventional control valves made from less corrosion-resistant materials.

Performance and Operational Differences

Flow Control and Pressure Regulation

Stainless steel control valves provide high precision in regulating flow and pressure. Their construction allows for minimal dead zones, reducing turbulence and ensuring stable fluid movement. Conventional valves may exhibit inconsistent performance in corrosive or high-temperature environments, resulting in pressure fluctuations and operational inefficiencies.

Temperature and Pressure Range

These valves are designed to withstand extreme conditions. Stainless steel maintains its structural integrity under high temperatures and pressure, whereas carbon steel or brass valves may deform or corrode over time. The broad operational range ensures reliable performance in both industrial and sanitary applications.

Sealing and Leakage Prevention

Sealing is a critical concern for all control valves. Stainless steel valves typically use advanced precision-cast or machined seats to reduce leakage risk. This contrasts with valves made from plastic or low-grade metals, which may develop leaks more quickly due to material fatigue or chemical attack.

Applications Across Industries

Stainless steel control valves are widely used in sectors requiring reliable and precise fluid management:

- Chemical and Petrochemical: Handling corrosive media while maintaining accurate flow and pressure.

- Water Treatment: Managing clean and wastewater with long-term reliability.

- Energy and Power Generation: Withstanding high pressures and temperatures in industrial pipelines.

- Food, Beverage, and Pharmaceutical: Ensuring hygienic operations and compliance with industry standards.

- High-End Manufacturing: Providing precision in cooling, lubrication, or process fluid systems.

By comparison, valves made from other metals are often limited to less demanding applications where corrosion and hygiene are not primary concerns.

Maintenance and Operational Efficiency

Reduced Maintenance Requirements

Due to the corrosion resistance and mechanical strength of stainless steel, these valves require less frequent maintenance. Components such as seals, stems, and seats experience lower wear rates, leading to fewer system shutdowns and lower lifecycle costs.

Sustainability and Resource Efficiency

Manufacturers like Shanghai Wakamatsu Metal Products Co., Ltd. emphasize lean production, sustainable workflows, and rigorous quality control. These practices extend the functional life of valves, reduce waste, and enhance overall efficiency for end-users.

After-Sales Support

Effective maintenance also involves responsive support. Stainless steel valve providers often offer technical assistance, product adjustments, and replacement components, ensuring continuous operation with minimal disruption.

Comparing Stainless Steel Control Valve with Other Valves

| Feature | Stainless Steel Control Valve | Conventional Valve |

|---|---|---|

| Corrosion Resistance | High | Moderate to low |

| Temperature Range | Wide | Limited |

| Pressure Handling | High | Moderate |

| Hygiene Compliance | High | Low |

| Maintenance Frequency | Low | Higher |

| Lifespan | Long | Shorter |

| Flow Precision | High | Variable |

This comparison highlights why industries requiring precise, reliable, and hygienic fluid control increasingly choose stainless steel control valves over alternatives.

Conclusion

The stainless steel control valve differentiates itself from conventional valves through its corrosion resistance, durability, hygienic design, and precise control capabilities. Its versatility in various valve types and suitability for demanding operational conditions make it an ideal choice for chemical, pharmaceutical, water treatment, energy, and high-end manufacturing applications.

With proper design, manufacturing, and maintenance, these valves provide long-term reliability and operational efficiency, reducing costs associated with downtime and frequent replacements.

FAQs

Q1: What is the main advantage of a stainless steel control valve over other materials?

A: Its corrosion resistance, durability, and hygienic properties make it suitable for demanding applications, offering longer service life and consistent performance.

Q2: Can stainless steel control valves handle high-pressure fluids?

A: Yes, these valves are designed to operate under high pressure and temperature conditions without compromising performance.

Q3: Are stainless steel control valves suitable for food and pharmaceutical industries?

A: Absolutely. Their smooth surfaces and resistance to microbial growth make them ideal for hygienic applications.

Q4: How does maintenance differ between stainless steel and conventional valves?

A: Stainless steel valves require less frequent maintenance due to their mechanical strength and corrosion resistance, reducing downtime and lifecycle costs.

Q5: Which industries benefit most from stainless steel control valves?

A: Industries such as chemical processing, water treatment, energy, high-end manufacturing, and pharmaceuticals benefit from the precision and durability of stainless steel valves.

English

English 日本語

日本語 中文

中文