The global market for stainless steel threaded fittings, particularly those adhering to NPT (National Pipe Thread) and BSPT (British Standard Pipe Tapered) standards, is experiencing robust growth. Driven by expanding applications in oil and gas, chemical processing, and food-grade industries, manuf...

READ MOREStainless Steel Gate Valve, Globe Valve, Check Valve Suppliers

Meet your diverse and refined fluid control needs. Gate valves offer full-bore flow, suitable for frequent opening and closing operations with minimal pressure drop. Globe valves excel at precise flow regulation and provide a tighter seal. Check valves automatically prevent backflow, ensuring unidirectional system operation. All three are forged from stainless steel, creating a comprehensive, reliable, and durable fluid control valve solution.

-

Stainless steel connectors

-

Stainless steel threaded connector

- Nipple,VN/VLN stainless steel double-ended male connector

- Nipple,VWN/VWLN stainless steel single-ended male connector

- WMFB/WMFLB stainless steel female connector, extension connector

- Socket,WPTS/WPTSB thin stainless steel double-ended female connector

- Socket,WHPTS/WHPTSB stainless steel single-ended female connector

- Socket,VSO/VHSO stainless steel straight-through female connector

- Socket,WPS stainless steel thick-wall straight-through female connector

- WM6N stainless steel hexagon nipple connector

- WMRN Stainless Steel Hexagon Reducing nippe connector

- WSFG stainless steel hexagonal equal-diameter adapter

- WBU/WMBU stainless steel bushing connectors

- WMF stainless steel male/female adapters

- WMFR stainless steel male/female reducing adapter

- WMS stainless steel flanged female banded socket

- WMRS stainless steel reducing female connectors

- W-KN series stainless steel quick-connect connectors

- VRHN stainless steel round hose connectors

- VRH stainless steel welding hose connectors

- VHS stainless steel hose connectors

- VHJ stainless steel hose connectors

- VHN, WCH, WMCH stainless steel hexagonal male hose fittings

- WCHF stainless steel hexagonal female thread hose fittings

- WCHL stainless steel L-shaped hose fittings

- WMU stainless steel female union fittings

- WMU2 stainless steel external union fittings WMU2 stainless steel male union fittings

- WMU3 stainless steel female and male union fittings

- WMUL stainless steel female union elbow fittings

- WMUL2 stainless steel female and male union elbow fittings

- WML stainless steel 90° elbow fittings

- WMRL stainless steel reducing elbow fittings

- WMSL stainless steel male/female elbow fitting

- WM45L stainless steel 45° elbow fitting

- WMX stainless steel cross fitting

- WMT stainless steel tee fitting

- WMRT stainless steel reducing tee fitting

- WMT-FMF-1/2 stainless steel main/female branch/female tee fitting

- WMT-FFM-1/2 stainless steel main/double female branch/male tee fitting

- WMT-MMF-1/2 stainless steel main/double male branch/female tee fitting

- WMYT-1/2 stainless steel full female tee fitting

- WMP stainless steel square plug fitting

- WMHP stainless steel hexagonal plug connector

- WCP stainless steel inner hexagonal plug connector

- WC stainless steel round pipe cap

- WHC stainless steel hexagonal pipe cap

- Stainless Steel Bulkhead Fittings Tt Series Female Thread/Male Thread

- Stainless Steel Bulkhead Fittings TTM Series Male/Female thread

- WSFG stainless steel hexagonal equal-diameter adapter-副本

-

Stainless steel bite type fittings

- W - Ktz Stainless Steel Straight-Through Bite Type Fitting

- W - KTZR Stainless Steel Reducing Straight-Through Bite Type Fitting

- W - Ktzm Stainless Steel Straight-Through Male Thread Bite Type Fitting

- W - Ktzf Stainless Steel Straight Through Female Thread Bite Type Fitting

- W - Ktl Stainless Steel Elbow Bite Type Fitting

- W - Ktlm Stainless Steel Male Elbow Bite Type Fitting

- W - Ktlf Stainless Steel Female Thread Elbow Bite Type Fitting

- W - Ktt Stainless Steel Tee Bite Type Fitting

- W - Ktt - Tmt Stainless Steel Tee Bite Type Fitting TMT

- W - Ktt - Tft Stainless Steel Tee Bite Type Fitting TFT

- W - Ktt - Ttm Stainless Steel Tee Branch Male Threaded Fitting

- W - Ktt - Ttf Stainless Steel Tee Bite Type Fitting TTF

- W - Ktx Stainless Steel Four-Way Bite Type Fitting

- W - Ktz - Cb Stainless Steel Straight-Through Bite Type Bulkhead Fitting

- W - Ktc Stainless Steel Tube Plug

- W - Ktp Stainless Steel Ferrule End Plug

- W - Ktq Stainless Steel Ferrule Assembly

- W - Ktg Stainless Steel Tube

-

Stainless steel quick connector

- W-Ksa Stainless Steel Quick Connector

- W-Kse Stainless Steel Quick Connector

- W-Ksf Stainless Steel Quick Connector

- W-Ksdp Stainless Steel Quick Connector

- W-Ksc Stainless Steel Handle Quick Connector

- W-Ksd Stainless Steel Handle Quick Connector

- W-Ksb Stainless Steel Lever Type Quick Connector

- W-Ksdc Stainless Steel Handle Quick Connector

- Stainless steel VCR connector

-

Stainless steel threaded connector

-

Stainless steel valves

-

Stainless steel ball valve

- Wv101/Wv101b Stainless Steel One-Piece Ball Valve

- Wv102/Wv102b Stainless Steel Two-Piece Ball Valve

- Wv102fm Stainless Steel Two-Piece Female And Male Thread Ball Valve

- Wv103 Stainless Steel Three-Piece Ball Valve

- Wv104 Stainless Steel Three-Way Ball Valve

- Wv301 Stainless Steel One-Piece Flange Ball Valve

- Wv302 Stainless Steel Two-Piece Flange Ball Valve

- Wv201ff Mini Stainless Steel Female Thread Ball Valve

- Wv202mm Mini Stainless Steel Male Ball Valve

- Wv203fm Mini Stainless Steel Female And Male Thread Ball Valve

- Wv204hm Pagoda-Shaped Stainless Steel Mini Male Ball Valve

- Wv205hf Pagoda-Shaped Stainless Steel Mini Female Ball Valve

- Stainless steel Y-type strainer

- Stainless steel gate valve/globe valve/check valve

- Stainless steel needle valve

-

Stainless steel ball valve

-

Stainless steel BUTT-WELDING fittings

-

Stainless steel flange

- Hoses and flexible pipes

-

Materials Main body: SCS13A/SCS14A. Seal: PTFE. Specifications Applicable media: Water, oil, and gas. Applicable temperature: ≤150°C. Maximum allowable pressure: 0.98 MPa (room temperature). Seal chec...VIEW MORE

-

Materials Main body: SCS13A/SCS14A. Seal: PTFE. Specifications Applicable media: Water, oil, and gas. Applicable temperature: ≤150°C. Maximum allowable pressure: 0.98 MPa (room temperature). Seal chec...VIEW MORE

-

Specifications Applicable media: Water, oil, and gas. Applicable temperature: ≤150°C. Maximum allowable pressure: 0.98 MPa (room temperature). Seal check pressure: 0.59 MPa (air pressure).VIEW MORE

-

Materials Main body: SCS13A/SCS14A. Seal: PTFE. Specifications Applicable media: Water, oil, and gas. Applicable temperature: ≤150°C. Maximum allowable pressure: 0.98 MPa (room temperature). Seal chec...VIEW MORE

-

-

Introduction Stainless steel butt weld fittings are crucial components in industrial piping systems, used for connecting pipes, valves, and other equipment. These fittings are welded to the pipes using a butt weld technique, ensuring a strong, leak-proof, and durable connection. Butt weld fittings a...

READ MORE -

What Is a Stainless Steel Camlock Coupling? A Stainless Steel Camlock (technically known as a Cam and Groove Coupling) is a quick-disconnect fluid transfer fitting that allows operators to connect or disconnect hoses without tools in seconds. Unlike threaded fittings or flanges that require wrenches...

READ MORE

What Are the Core Advantages of Stainless Steel Gate Valves?

In today's rapidly changing industrial landscape, from construction and municipal engineering to chemical and food processing equipment, the stability of fluid control systems is impacting production efficiency, safety, and sustainable operation. Among numerous valve products, Stainless Steel Gate Valves are increasingly becoming the market's preferred choice due to their superior corrosion resistance, sealing reliability, and long service life.

I. What Are the Technological Advantages of Stainless Steel Gate Valves?

The core function of a gate valve is to completely open and close the fluid passage, and the use of stainless steel ensures its high stability even in harsh environments.

1. Excellent Corrosion Resistance

The addition of stainless steel allows gate valves to remain rust-free for extended periods in high humidity, acid and alkali, seawater, and high-temperature environments, without experiencing metal fatigue or surface peeling. Gate valves using high-grade stainless steels such as 304 and 316L are particularly common in the chemical and food industries.

2. Easy Opening and Closing, Reliable Sealing

Thanks to their wedge or resilient gate structure, stainless steel gate valves experience low friction and are less prone to jamming during operation. They maintain a tight seal even under high pressure, ensuring safe system operation.

3. Wide Range of Media Adaptability

Whether it's steam, oil, pure water, corrosive chemicals, or low-particle fluids, stainless steel gate valves maintain stable performance. Their versatility reduces maintenance and replacement costs for businesses.

II. Why Such a Wide Range of Applications?

Stainless steel gate valves, with their multifunctional characteristics, have become indispensable in many industries:

- Building and Fire Protection Systems: High reliability and pressure resistance make them suitable for fire protection piping networks and equipment rooms.

- Industrial Manufacturing Equipment: Ideal for flow control in steam systems, cooling systems, and mechanical pipelines.

- Petroleum and Chemical Industry: Corrosion and high-temperature resistance are essential for process pipelines.

- Food and Pharmaceutical Industry: Compliant with sanitary standards to ensure purity and prevent contamination.

- Marine and Offshore Equipment: Excellent seawater corrosion resistance ensures long-term durability.

The reasons for its widespread use are simple: reliability, durability, and cost-effectiveness.

III. Intense Market Competition: How Should Companies Choose Suppliers?

The valve market is diverse, and manufacturers vary greatly in technical strength and manufacturing stability. Selection should consider:

1. High-Precision Manufacturing Capability

Gate valves require precise machining for key components such as the valve body, stem, and gate. Precision directly affects sealing performance and product lifespan.

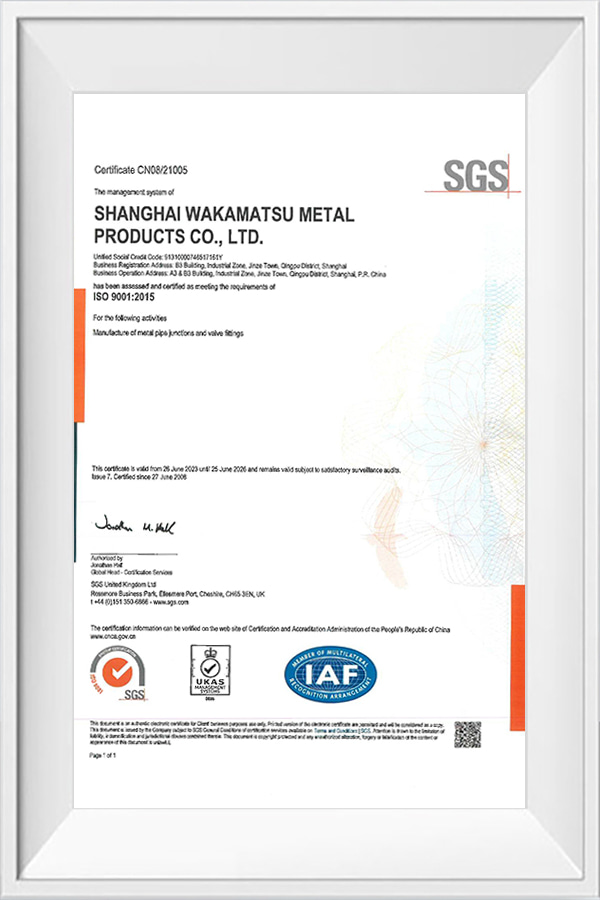

2. Rigorous Quality Control System

Qualified stainless steel gate valves undergo multiple tests, including pressure, sealing, and corrosion resistance testing.

3. Long-Term, Stable Supply Capability

Consistent supply is crucial for engineering projects and manufacturing industries.

Few brands combine high-precision manufacturing, strict quality control, and international-grade quality. Shanghai Wakamatsu Metal Products Co., Ltd. stands out as a leading example.

IV. What Makes Shanghai Wakamatsu Stand Out?

Founded in 2003, Shanghai Wakamatsu Metal Products Co., Ltd. is a Japan-funded manufacturer specializing in stainless steel valves and pipe fittings. With over two decades of industry expertise, the company continuously emphasizes “precision manufacturing” as its core competitiveness.

1. Japanese Manufacturing DNA + Chinese Production Efficiency

The company integrates Japanese manufacturing standards into its production system, including:

- Strict precision control

- Standardized process flow

- Comprehensive quality management from inspection to packaging

Combined with advanced Chinese production facilities, this ensures both consistent quality and efficient delivery.

2. Focus on Stainless Steel Valves, Focus on Professionalism

Shanghai Wakamatsu specializes in stainless steel threaded pipe fittings and various valve types. As a professional stainless steel gate valve wholesaler and OEM/ODM factory, the company offers customized solutions for global clients.

3. International Trust, Global Exports

Due to stable quality and technical reliability, products are widely exported to:

- Japan (core market)

- Europe

- Southeast Asia

Customers choose Shanghai Wakamatsu products for their reliability, precision, and durability.

4. Serving Engineering Projects and Specialized Equipment

Applications include:

- Building and Fire Protection Systems

- Precision Industrial Equipment

- Chemical and Pharmaceutical Industries

- High-End Machinery Manufacturing

- Safety and Fluid Control Systems

V. How to Determine if a Stainless Steel Gate Valve Is Worth the Investment?

You can evaluate product value through the following criteria:

1. Genuine Material Grade

Reputable manufacturers indicate material grades like 304, 316, and 316L and provide material reports.

2. Comprehensive Testing

Qualified gate valves undergo pressure, sealing, and torque testing to ensure performance.

3. Precision Machining Quality

High-precision machining ensures:

- No leakage or seepage

- Smooth switching

- Longer lifespan

4. Stable Supply Capability and After-Sales Service

Professional valve projects require reliable technical support and continuous supply stability.

Shanghai Wakamatsu Metal has extensive experience in these areas, earning global customers’ trust with its proven performance.

As industrial equipment and infrastructure continue to upgrade, the demand for reliable fluid control systems increases. A high-quality stainless steel gate valve not only enhances system stability but also reduces long-term maintenance costs.

English

English 日本語

日本語 中文

中文