The global market for stainless steel threaded fittings, particularly those adhering to NPT (National Pipe Thread) and BSPT (British Standard Pipe Tapered) standards, is experiencing robust growth. Driven by expanding applications in oil and gas, chemical processing, and food-grade industries, manuf...

READ MOREInclined Stainless Steel Y-Type Strainer Suppliers

Acting as the "guardian" of the pipeline system, it effectively intercepts and removes solid impurities from the fluid, protecting downstream valves, pumps, and instruments from damage. The stainless steel Y-type strainer features a tilted filter basket design, offering a large filtration area, minimal pressure drop, and convenient filter cleaning without disconnecting the main line, ensuring production continuity. It is a critical pre-filtration device for extending equipment life and ensuring product quality.

-

Stainless steel connectors

-

Stainless steel threaded connector

- Nipple,VN/VLN stainless steel double-ended male connector

- Nipple,VWN/VWLN stainless steel single-ended male connector

- WMFB/WMFLB stainless steel female connector, extension connector

- Socket,WPTS/WPTSB thin stainless steel double-ended female connector

- Socket,WHPTS/WHPTSB stainless steel single-ended female connector

- Socket,VSO/VHSO stainless steel straight-through female connector

- Socket,WPS stainless steel thick-wall straight-through female connector

- WM6N stainless steel hexagon nipple connector

- WMRN Stainless Steel Hexagon Reducing nippe connector

- WSFG stainless steel hexagonal equal-diameter adapter

- WBU/WMBU stainless steel bushing connectors

- WMF stainless steel male/female adapters

- WMFR stainless steel male/female reducing adapter

- WMS stainless steel flanged female banded socket

- WMRS stainless steel reducing female connectors

- W-KN series stainless steel quick-connect connectors

- VRHN stainless steel round hose connectors

- VRH stainless steel welding hose connectors

- VHS stainless steel hose connectors

- VHJ stainless steel hose connectors

- VHN, WCH, WMCH stainless steel hexagonal male hose fittings

- WCHF stainless steel hexagonal female thread hose fittings

- WCHL stainless steel L-shaped hose fittings

- WMU stainless steel female union fittings

- WMU2 stainless steel external union fittings WMU2 stainless steel male union fittings

- WMU3 stainless steel female and male union fittings

- WMUL stainless steel female union elbow fittings

- WMUL2 stainless steel female and male union elbow fittings

- WML stainless steel 90° elbow fittings

- WMRL stainless steel reducing elbow fittings

- WMSL stainless steel male/female elbow fitting

- WM45L stainless steel 45° elbow fitting

- WMX stainless steel cross fitting

- WMT stainless steel tee fitting

- WMRT stainless steel reducing tee fitting

- WMT-FMF-1/2 stainless steel main/female branch/female tee fitting

- WMT-FFM-1/2 stainless steel main/double female branch/male tee fitting

- WMT-MMF-1/2 stainless steel main/double male branch/female tee fitting

- WMYT-1/2 stainless steel full female tee fitting

- WMP stainless steel square plug fitting

- WMHP stainless steel hexagonal plug connector

- WCP stainless steel inner hexagonal plug connector

- WC stainless steel round pipe cap

- WHC stainless steel hexagonal pipe cap

- Stainless Steel Bulkhead Fittings Tt Series Female Thread/Male Thread

- Stainless Steel Bulkhead Fittings TTM Series Male/Female thread

- WSFG stainless steel hexagonal equal-diameter adapter-副本

-

Stainless steel bite type fittings

- W - Ktz Stainless Steel Straight-Through Bite Type Fitting

- W - KTZR Stainless Steel Reducing Straight-Through Bite Type Fitting

- W - Ktzm Stainless Steel Straight-Through Male Thread Bite Type Fitting

- W - Ktzf Stainless Steel Straight Through Female Thread Bite Type Fitting

- W - Ktl Stainless Steel Elbow Bite Type Fitting

- W - Ktlm Stainless Steel Male Elbow Bite Type Fitting

- W - Ktlf Stainless Steel Female Thread Elbow Bite Type Fitting

- W - Ktt Stainless Steel Tee Bite Type Fitting

- W - Ktt - Tmt Stainless Steel Tee Bite Type Fitting TMT

- W - Ktt - Tft Stainless Steel Tee Bite Type Fitting TFT

- W - Ktt - Ttm Stainless Steel Tee Branch Male Threaded Fitting

- W - Ktt - Ttf Stainless Steel Tee Bite Type Fitting TTF

- W - Ktx Stainless Steel Four-Way Bite Type Fitting

- W - Ktz - Cb Stainless Steel Straight-Through Bite Type Bulkhead Fitting

- W - Ktc Stainless Steel Tube Plug

- W - Ktp Stainless Steel Ferrule End Plug

- W - Ktq Stainless Steel Ferrule Assembly

- W - Ktg Stainless Steel Tube

-

Stainless steel quick connector

- W-Ksa Stainless Steel Quick Connector

- W-Kse Stainless Steel Quick Connector

- W-Ksf Stainless Steel Quick Connector

- W-Ksdp Stainless Steel Quick Connector

- W-Ksc Stainless Steel Handle Quick Connector

- W-Ksd Stainless Steel Handle Quick Connector

- W-Ksb Stainless Steel Lever Type Quick Connector

- W-Ksdc Stainless Steel Handle Quick Connector

- Stainless steel VCR connector

-

Stainless steel threaded connector

-

Stainless steel valves

-

Stainless steel ball valve

- Wv101/Wv101b Stainless Steel One-Piece Ball Valve

- Wv102/Wv102b Stainless Steel Two-Piece Ball Valve

- Wv102fm Stainless Steel Two-Piece Female And Male Thread Ball Valve

- Wv103 Stainless Steel Three-Piece Ball Valve

- Wv104 Stainless Steel Three-Way Ball Valve

- Wv301 Stainless Steel One-Piece Flange Ball Valve

- Wv302 Stainless Steel Two-Piece Flange Ball Valve

- Wv201ff Mini Stainless Steel Female Thread Ball Valve

- Wv202mm Mini Stainless Steel Male Ball Valve

- Wv203fm Mini Stainless Steel Female And Male Thread Ball Valve

- Wv204hm Pagoda-Shaped Stainless Steel Mini Male Ball Valve

- Wv205hf Pagoda-Shaped Stainless Steel Mini Female Ball Valve

- Stainless steel Y-type strainer

- Stainless steel gate valve/globe valve/check valve

- Stainless steel needle valve

-

Stainless steel ball valve

-

Stainless steel BUTT-WELDING fittings

-

Stainless steel flange

- Hoses and flexible pipes

-

Materials Main body: SCS13A/SCS14A. Filter: SUS304/SUS316. Gasket: PTFE. Specifications Applicable media: Water, oil, and gas. Applicable temperature: ≤150°C. Maximum allowable pressure: 1.96 MPa (roo...VIEW MORE

-

-

Introduction Stainless steel butt weld fittings are crucial components in industrial piping systems, used for connecting pipes, valves, and other equipment. These fittings are welded to the pipes using a butt weld technique, ensuring a strong, leak-proof, and durable connection. Butt weld fittings a...

READ MORE -

What Is a Stainless Steel Camlock Coupling? A Stainless Steel Camlock (technically known as a Cam and Groove Coupling) is a quick-disconnect fluid transfer fitting that allows operators to connect or disconnect hoses without tools in seconds. Unlike threaded fittings or flanges that require wrenches...

READ MORE

Why is the Inclined Stainless Steel Y-Type Strainer a Key Guardian in Industrial Systems?

Introduction

In complex fluid transport systems, attention is often focused on pumps, valves, or control equipment, overlooking a small but crucial component—the Inclined Stainless Steel Y-Type Strainer. Despite its small size, it plays a significant role in the stability and safety of the entire system. Many engineers even describe it as the "gatekeeper of the system," as it determines whether downstream equipment can operate in a clean and stable environment.

What is the structural appeal of the Inclined Stainless Steel Y-Type Strainer?

The Y-type filter's prominent position in industry is closely related to its unique structure. The inclined design naturally separates fluid from impurities; solid particles are collected in the filter chamber, while clean media flows smoothly through the pipes. This ingenious arrangement of physical structures allows it to maintain high filtration efficiency even during long-term operation.

Drainage and maintenance advantages

More importantly, the inclined angle facilitates drainage, allowing for the cleaning of accumulated impurities without disassembling the equipment, reducing downtime and improving efficiency. This advantage is particularly pronounced in industries sensitive to equipment maintenance costs.

Why has stainless steel become the industry standard?

In numerous applications, stainless steel has become the default choice for professional engineers. This is not only due to the material's inherent strength but also its ability to maintain stable performance in harsh environments.

Corrosion resistance and cleanliness

Stainless steel possesses natural corrosion resistance, providing reliable protection against water, steam, oil, and chemical media. For fields requiring high cleanliness or hygiene standards, such as food engineering, pharmaceutical equipment, or high-end manufacturing, stainless steel Y-type filters not only meet basic requirements but can also withstand the challenges of frequent cleaning and disinfection.

High-temperature and high-pressure performance

Stainless steel maintains its structural strength under high temperature and pressure conditions, making inclined stainless steel Y-type filters stable and reliable in high-load scenarios such as industrial equipment, HVAC systems, and fire protection systems.

Application Scenarios: A Small Component Leading to System Reliability

When people talk about Y-type filters, they are often misled by their "simplicity." However, the more complex and dynamic an industrial system is, the more it needs such a stable and reliable component to maintain overall balance.

Building engineering

In building engineering, inclined stainless steel Y-type filters ensure the stable operation of cooling water and HVAC systems, preventing building management from incurring huge maintenance costs due to minor impurities.

Industrial equipment and fire safety

In industrial equipment, it protects precision pumps and control valves from abrasive wear; in fire safety systems, it serves as the fundamental safeguard ensuring unobstructed sprinkler lines. Its presence, though unassuming, determines the long-term stable operation of the entire system.

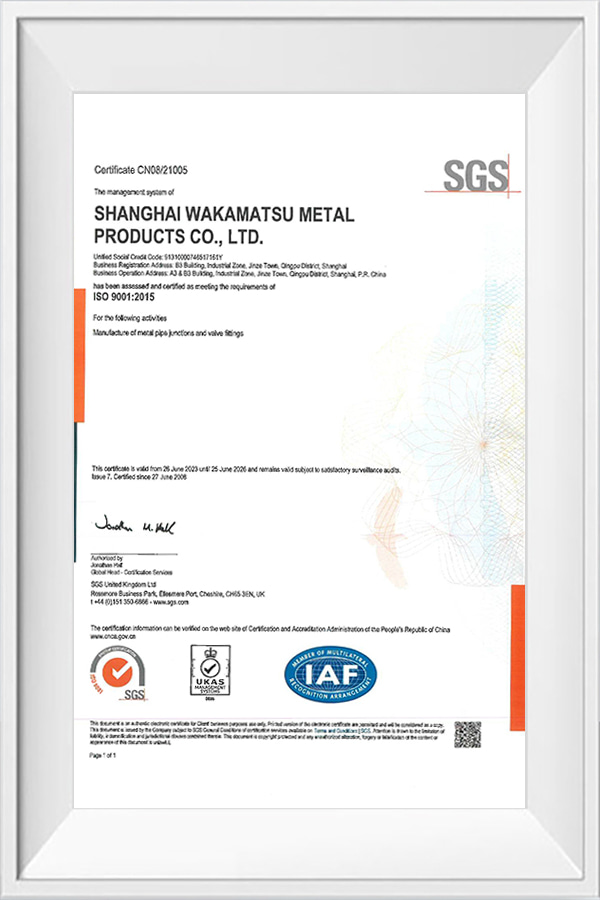

Why do global customers choose Shanghai Wakamatsu Metal Products Co., Ltd.?

As a professional supplier of filters and stainless steel fittings, Shanghai Wakamatsu Metal Products Co., Ltd. is committed to integrating high reliability and precision manufacturing into every product.

Since its inception, we have inherited the craftsmanship of Japanese manufacturing while continuously investing in advanced automated production equipment, making stability, precision, and durability the core competitiveness of our products. In the production of our Inclined Stainless Steel Y-Type Strainer, we not only pursue structural rigor but also emphasize the comprehensive performance of materials, welding, thread precision, and pressure resistance.

We provide Wholesale and OEM/ODM services to the global market, customizing Y-type filters of different sizes, filtration accuracies, and application requirements for our customers. This is why our products are widely used in markets with stringent quality requirements, such as Japan, Europe, and Southeast Asia.

For many engineering and system integrators, choosing Shanghai Wakamatsu Metal Products Co., Ltd. is not just choosing a filter supplier, but choosing a reliable partner and a manufacturer responsible for quality and delivery.

Company Quick Facts

| Founded | 2003 |

| Specialization | Stainless steel screwed fittings, valves, bite type tube fittings, Inclined Stainless Steel Y-Type Strainers |

| Services | Wholesale, OEM/ODM, Customized solutions |

| Markets | Japan, Europe, Southeast Asia and global clients |

| Core strengths | Japanese precision manufacturing, advanced production facilities, quality control, long-term industry expertise |

Where will Y-type filters go in the future?

With industrial automation, smart manufacturing, and sustainable development becoming trends, the requirements for filtration equipment are constantly increasing. Inclined stainless steel Y-type filters, as a fundamental component, will also show new development directions in the future, such as higher filtration accuracy, lower energy consumption, longer lifespan, and more intelligent health monitoring designs.

For Shanghai Wakamatsu Metal Products Co., Ltd., which has always focused on the manufacture of stainless steel fluid fittings, this is both a challenge and an opportunity. With over two decades of experience, a mature process system, and a meticulous attention to detail, we will continue to provide global customers with high-quality, high-reliability Inclined Stainless Steel Y-Type Strainer solutions.

Conclusion

When you see a system operating smoothly, quietly, and reliably, it may well be the unnoticed contribution of an Inclined Stainless Steel Y-Type Strainer silently performing its role as the system's guardian. Choosing the right strainers and a trustworthy manufacturer like Shanghai Wakamatsu Metal Products Co., Ltd. is a practical step toward ensuring long-term system stability and reducing lifecycle costs.

English

English 日本語

日本語 中文

中文